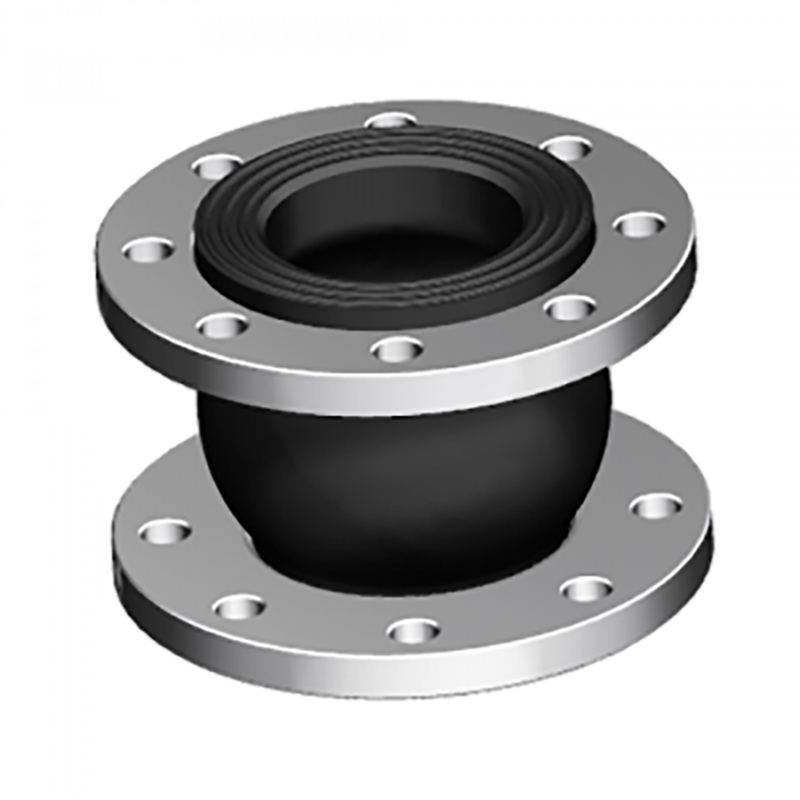

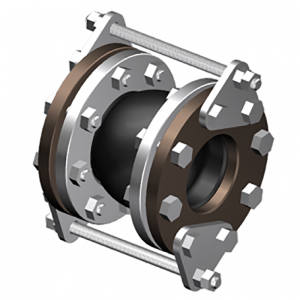

High Quality China Rubber Expansion Joint Screwed or Flanged DIN Pn10-16 BS4504 ANSI Cl150 Flanged Type Size DN25-DN600 or Screwed Type 1/2″-3″ with Tie Rods Single Double-Sphere

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Quality China Rubber Expansion Joint Screwed or Flanged DIN Pn10-16 BS4504 ANSI Cl150 Flanged Type Size DN25-DN600 or Screwed Type 1/2″-3″ with Tie Rods Single Double-Sphere, Adhering on the enterprise philosophy of ‘customer 1st, forge ahead’, we sincerely welcome customers from in your house and overseas to cooperate with us provide you with most effective support!

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China Rubber, Joint, We are confident that we’re able to provide you with opportunities and is going to be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of merchandise that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

Details

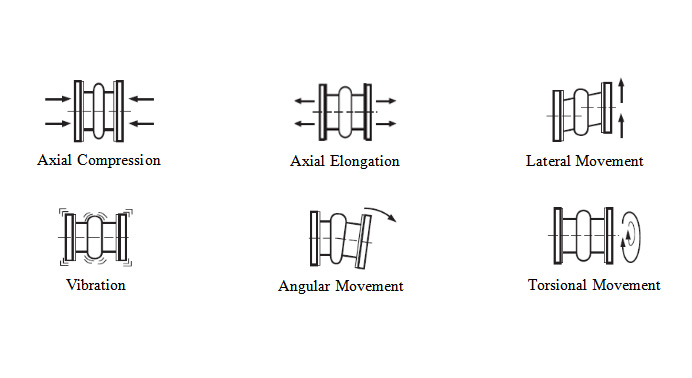

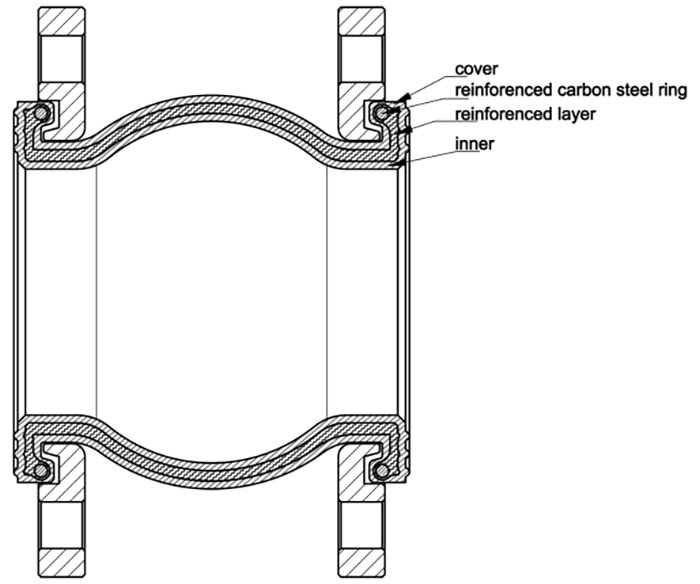

The single-arch product can reduce the vibration and noise, which can also solve the axial/lateral/angular movements/eccentric problems. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Single Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Standard O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

135 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

205 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

240 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

Single Arch-130MM |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

1 1/2″ |

40 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2″ |

50 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2 1/2″ |

65 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

3″ |

80 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

4″ |

100 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

5″ |

125 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

6″ |

150 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

8″ |

200 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

10″ |

250 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

12″ |

300 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

Single Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1″ |

25 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

37° |

225 |

26 |

|

1 1/4″ |

32 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

31° |

225 |

26 |

|

1 1/2″ |

40 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

27° |

225 |

26 |

|

2″ |

50 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

20° |

225 |

26 |

|

2 1/2″ |

65 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

17° |

225 |

26 |

|

3″ |

80 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

14° |

225 |

26 |

|

4″ |

100 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

14° |

225 |

26 |

|

5″ |

125 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

11° |

225 |

26 |

|

6″ |

150 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

9° |

225 |

26 |

|

8″ |

200 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

7° |

225 |

26 |

|

10″ |

250 |

8″ |

1″ |

5/8″ |

±3/4″ |

7° |

225 |

26 |

|

12″ |

300 |

8″ |

1″ |

5/8″ |

±3/4″ |

6° |

225 |

26 |

|

14″ |

350 |

8″ |

1″ |

5/8″ |

±3/4″ |

5° |

150 |

26 |

|

16″ |

400 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

18″ |

450 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

20″ |

500 |

8″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

24″ |

600 |

10″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

Single Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length(mm) |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1 1/4 |

32 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

1 1/2 |

40 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 |

50 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 1/2 |

65 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

3 |

80 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

4 |

100 |

150 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

5 |

125 |

175 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

6 |

150 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

8 |

200 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

10 |

250 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

12 |

300 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

Single Arch-Domestic Market |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

150 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

210 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

230 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

245 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Quality China Rubber Expansion Joint Screwed or Flanged DIN Pn10-16 BS4504 ANSI Cl150 Flanged Type Size DN25-DN600 or Screwed Type 1/2″-3″ with Tie Rods Single Double-Sphere, Adhering on the enterprise philosophy of ‘customer 1st, forge ahead’, we sincerely welcome customers from in your house and overseas to cooperate with us provide you with most effective support!

High Quality China Rubber, Joint, We are confident that we’re able to provide you with opportunities and is going to be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of merchandise that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang